Plant simulation is transforming the landscape of manufacturing, allowing businesses to optimize their operations and improve efficiency. This innovative concept applies advanced modeling techniques to create virtual representations of production processes, enabling companies to visualize workflows, identify bottlenecks, and test solutions before implementation.

By leveraging the benefits of plant simulation, organizations can enhance decision-making capabilities, reduce costs, and increase productivity, making it an invaluable tool in today’s competitive industrial environment.

Introduction to Plant Simulation

Plant simulation is a sophisticated modeling technique used in manufacturing environments to replicate and analyze the performance of production systems. By creating virtual replicas of physical processes, plant simulation allows manufacturers to evaluate different operational scenarios without disrupting actual production. This approach aids in understanding complex interactions within the manufacturing process, paving the way for improved efficiency and effectiveness in operations.

The implementation of plant simulation in production environments offers several notable benefits. It enables manufacturers to identify bottlenecks, optimize resource allocation, and enhance scheduling. By leveraging simulation, companies can reduce operational costs and improve overall productivity while maintaining quality standards. Furthermore, it supports decision-making by providing a risk-free environment to test hypotheses and validate changes before they are put into practice.

Primary Components of Plant Simulation Systems

Several key components are integral to the functionality of plant simulation systems. These components work together to create a comprehensive representation of manufacturing processes.

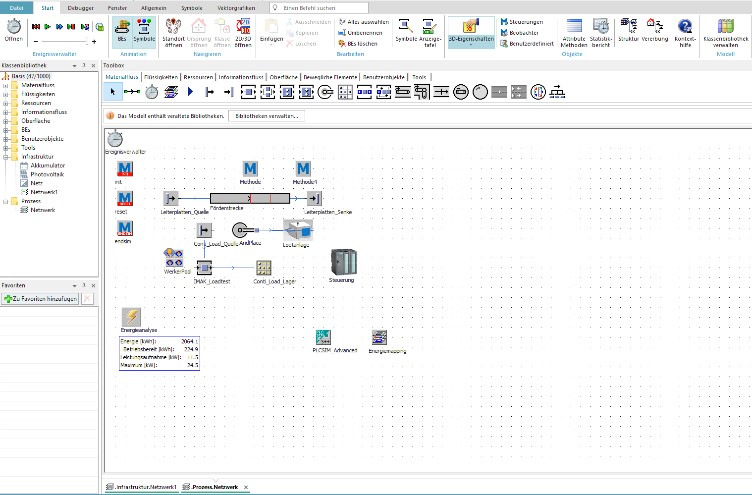

- Simulation Software: This is the core tool used to model the production environment. Popular software options include AnyLogic, Siemens Plant Simulation, and FlexSim, each providing unique features for process modeling and analysis.

- Data Input: Accurate data collection is crucial for effective simulation. This includes information about process times, resource availability, and material flow, which must be gathered from existing operations.

- Modeling Techniques: Various modeling approaches, such as discrete event simulation and system dynamics, are employed depending on the complexity and nature of the manufacturing process. These methods help in visualizing the flow and interactions of different components within the system.

- Visualization Tools: Effective simulation relies on visualization to interpret data and results clearly. Graphs, charts, and 3D animations provide insights into system performance and facilitate easier communication of findings to stakeholders.

“The power of plant simulation lies in its ability to visualize the unseen, revealing operational inefficiencies and guiding improvement strategies.”

Each component plays a pivotal role in ensuring the simulation accurately reflects the physical plant, enabling manufacturers to make informed decisions that drive efficiency and effectiveness in their operations.

Applications of Plant Simulation

Plant simulation techniques have emerged as crucial tools for enhancing operational efficiency across various sectors. Their ability to model complex processes allows businesses to visualize production workflows, optimize resource allocation, and predict potential bottlenecks. This leads to improved performance, reduced costs, and a more agile response to market demands.

Different industries have successfully integrated plant simulation into their operations, reaping substantial benefits. The utilization of simulation tools enables organizations to experiment with different scenarios without the risks associated with real-world implementation. The following are key industries that have leveraged plant simulation effectively:

Industries Benefiting from Plant Simulation Techniques

Several sectors have adopted plant simulation to streamline their operations. The diversity of applications demonstrates the versatility and effectiveness of these techniques. Below are notable industries and their respective uses:

- Manufacturing: Manufacturers utilize plant simulation to design layouts, improve assembly line efficiency, and manage inventory levels. For example, a major automotive manufacturer implemented a simulation model that reduced production cycle times by 20%.

- Healthcare: Hospitals employ plant simulation to optimize patient flow and resource allocation. A well-known hospital successfully used simulation to reconfigure its emergency department, resulting in a 30% decrease in patient wait times.

- Logistics: Supply chain companies use simulation to analyze and improve distribution networks. A logistics firm was able to enhance delivery times through a simulation that optimized routing and scheduling, achieving a 15% reduction in operational costs.

- Food and Beverage: The industry relies on simulation for process optimization and quality control. A leading beverage company reduced production waste by 25% using simulation tools to test different bottling configurations.

- Pharmaceuticals: Simulation aids in managing production schedules and regulatory compliance. A pharmaceutical firm utilized plant simulation to streamline its drug manufacturing process, resulting in a 40% faster time-to-market for new medications.

Successful Plant Simulation Projects and Their Outcomes

Numerous organizations have undertaken successful plant simulation projects, showcasing measurable improvements in their operational efficiencies. The following examples highlight the positive outcomes derived from these initiatives:

- Automotive Assembly Plant: A leading automotive manufacturer executed a simulation project to redesign its assembly line. The result was a 25% increase in throughput and significant savings in labor costs.

- Pharmaceutical Production: A global pharmaceutical company implemented a simulation for its production processes, leading to a 30% reduction in production downtime and a notable increase in compliance with FDA regulations.

- Food Processing Facility: By using plant simulation, a food processing facility was able to adjust its production schedule dynamically, resulting in a 20% decrease in overtime labor costs and improved product freshness.

Enhancing Decision-Making Processes in Production Planning

Plant simulation plays a vital role in aiding decision-making processes, particularly in production planning. By providing a virtual environment to test various scenarios, businesses can make informed choices that enhance operational efficiency.

The decision-making capabilities are significantly improved through the following methods:

- Scenario Analysis: Simulation allows planners to evaluate the impact of different operational strategies without disrupting actual production. This leads to better forecasting and planning accuracy.

- Resource Optimization: By simulating various resource allocation strategies, organizations can identify the most efficient use of assets, resulting in cost reductions and higher productivity.

- Risk Management: Simulation helps identify potential risks and bottlenecks before they manifest in real operations, enabling preemptive actions that mitigate negative impacts on production.

Methods and Techniques in Plant Simulation

Plant simulation utilizes various modeling techniques and methodologies to replicate and analyze processes within manufacturing and production environments. Understanding these methods is essential for creating accurate models that can provide valuable insights into system performance, bottlenecks, and resource utilization. This section delves into the different modeling techniques, the steps involved in creating a plant simulation model, and the best practices for validating and verifying these models before implementation.

Modeling Techniques in Plant Simulation

Several modeling techniques are prevalent in plant simulation, each with its distinct advantages and applications. These techniques help in representing complex systems and processes effectively. The following list Artikels some of the most commonly used modeling techniques:

- Discrete Event Simulation (DES): This technique models the operation of a system as a sequence of events in time. It is highly effective for systems where changes occur at distinct points in time, such as manufacturing processes where machines are turned on and off.

- Agent-Based Modeling (ABM): ABM focuses on individual entities (agents) within the system that interact with one another and with their environment. This is particularly useful for simulating human behavior or adaptive processes in complex systems.

- System Dynamics (SD): This technique employs differential equations to model the continuous change within a system. It is often used for high-level strategic simulations and long-term policy analysis.

- Hybrid Simulation: Combining different simulation methodologies, hybrid simulation leverages the strengths of both discrete and continuous approaches to model complex systems more accurately.

Steps in Creating a Plant Simulation Model

Developing a plant simulation model requires a structured approach to ensure that all relevant aspects of the system are captured accurately. Here is a systematic overview of the steps involved:

- Define the Objectives: Clearly Artikel the goals of the simulation, including what questions need to be answered and which performance metrics are critical.

- Collect Data: Gather detailed information about the system, including process flows, resource capacities, and historical performance data.

- Design the Model: Create a model layout that reflects the physical and logical structure of the system. This includes defining entities, resources, processes, and interactions.

- Implement the Model: Use simulation software tools to build the model based on the design specifications. This involves coding the logic for processes and interactions.

- Run Simulations: Execute the model under various scenarios to observe system behavior and performance outcomes. This helps in understanding the implications of different input variables.

Validation and Verification of Simulation Models

Before deploying plant simulation models, it is crucial to validate and verify them to ensure accuracy and reliability. This process involves several steps aimed at providing confidence in the model’s predictions.

- Verification: This step ensures that the model was implemented correctly. Techniques include code reviews, debugging, and stepwise execution to confirm that the model behaves as intended.

- Validation: Validation ensures that the model accurately represents the real-world system. This can be done by comparing simulation outputs with actual performance data. Statistical methods can help quantify the degree of accuracy.

- Scenario Testing: Running the model under different scenarios can reveal its robustness. This helps to identify potential weaknesses and areas for improvement.

- Stakeholder Review: Engaging stakeholders in the review process can provide valuable feedback. Their insights can help verify that the model aligns with operational realities and expectations.

Successful validation and verification enhance the credibility of simulation models, ensuring that they provide reliable insights for decision-making.

Future Trends in Plant Simulation

The landscape of plant simulation is undergoing transformative changes driven by advancements in technology. As industries strive for efficiency and innovation, the integration of emerging technologies promises to reshape how simulations are conducted. This segment explores the future trends that are likely to define the domain of plant simulation, emphasizing the roles of artificial intelligence, machine learning, and real-time data integration.

Emerging Technologies Impacting Plant Simulation

The integration of cutting-edge technologies is crucial for enhancing the scope and effectiveness of plant simulation. Key technologies shaping the future include:

- Artificial Intelligence (AI): AI algorithms can analyze vast datasets to optimize production schedules and predict equipment failures, significantly reducing downtime.

- Machine Learning: By utilizing historical data, machine learning models improve predictive accuracy over time, helping to refine simulations based on changing operational conditions.

- Internet of Things (IoT): IoT devices facilitate the collection of real-time data from manufacturing processes, providing insights that can enhance simulation accuracy.

- Digital Twins: Creating digital replicas of physical assets enables simulation and analysis of performance under various scenarios, leading to better decision-making.

Comparison of Traditional Simulation Methods and Advanced Approaches

Traditional simulation methods often involve static models that may not account for the dynamic nature of manufacturing environments. In contrast, advanced approaches, particularly those leveraging AI and machine learning, offer adaptive solutions. The advantages include:

- Enhanced Predictive Capabilities: Traditional simulations rely on historical data, while machine learning algorithms continuously learn from new data, improving predictions.

- Real-Time Adjustments: Advanced simulation models can adjust parameters in real time based on incoming data, ensuring accuracy and relevance.

- Scalability: AI-driven simulations can easily adapt to larger and more complex systems, unlike traditional methods that may struggle with scalability.

- Cost Efficiency: The optimization provided by AI can lead to substantial cost savings by minimizing waste and maximizing resource utilization.

Importance of Real-Time Data Integration

Real-time data integration is becoming a cornerstone of future plant simulation applications. The ability to incorporate live data feeds allows for immediate responses to operational changes, significantly enhancing the simulation’s value. Key aspects include:

- Accurate Decision-Making: Real-time data helps managers make informed decisions quickly, responding effectively to unexpected events.

- Continuous Improvement: By using real-time data, simulations can continuously evolve, leading to ongoing improvements in processes and efficiency.

- Increased Responsiveness: Industries can rapidly adapt to market demands and operational challenges, maintaining competitiveness in a fast-paced environment.

- Holistic Insights: Integrating data from various sources provides a comprehensive view of operations, facilitating better overall management.

“Real-time data integration not only enhances simulation accuracy but also enables organizations to maintain agility in their operations, crucial for success in modern industries.”

Q&A

What is plant simulation used for?

Plant simulation is used to model, analyze, and optimize manufacturing processes to improve efficiency and decision-making.

Which industries benefit from plant simulation?

Industries such as automotive, aerospace, electronics, and consumer goods frequently utilize plant simulation to enhance their production systems.

How does plant simulation improve decision-making?

By providing a virtual environment to test scenarios, plant simulation helps managers evaluate options and make informed decisions based on data-driven insights.

What tools are commonly used for plant simulation?

Common tools for plant simulation include AnyLogic, FlexSim, and SIMUL8, which offer various modeling capabilities and user-friendly interfaces.

How can real-time data enhance plant simulation?

Real-time data integration allows for more accurate simulations, enabling businesses to respond quickly to changes in production conditions and optimize their processes continually.